DUAL

FUEL SOLUTIONS

Over 50 locations worldwide

The Dual Fuel technology is based on the concept that inserting additional energy into the combustion chamber of Diesel Engines in the form of natural gas allows the engine to use less diesel to produce the same power. Typically, upto 70 percent of the diesel fuel normally used can be safely displayed with natural gas.

Conversion from diesel to dual-fuel operation brings considerable savings in terms of fuel costs as well as reduced emissions. In the dual-fuel systems from KPJ classic, tried-and-tested components are combined to ensure precise control of gas and diesel injection. In every operating condition, they guarantee optimum engine behaviour and are perfectly adapted to the requirements of the application in question.

How it works?

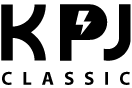

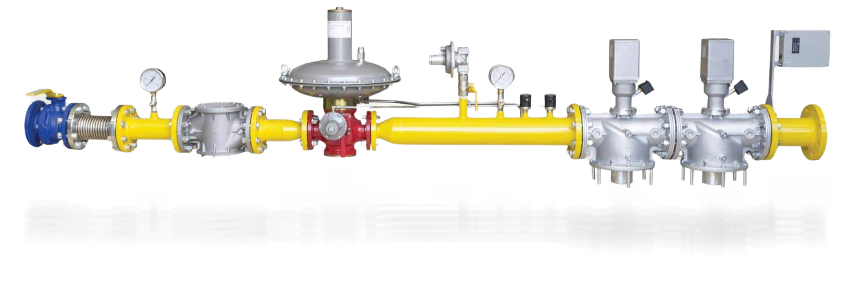

Gas Train

The gas used for Dual Fueling is sourced from either piped gas or from local storage. It is injected into the combustion air stream via a Gas Train consisting of a gas filter, a gas pressure regulator and a solenoid valve. A throttle valve at the end controls the proportion of the gas injected. The gas train is designed to accept input gas at low pressure and deliver it to the engine at a slightly negative pressure.

Mixer

Dual Fuel System delivers fuel gas to the combustion cylinders via the Gas Train into a special Air-Gas Mixer. The mixer is installed on the engine air inlet before the Turbo charger. Combustion is commenced by Diesel as the ignition source and followed by ignition of the Gas.

Controller

A state-of-the-art electronic controller continuously monitors critical engine parameters through the operation and transitions seamlessly from ‘Dual fuel’ to ‘diesel only’ mode if they cross the preset limits. It provides complete safety to the engine while operating in the Dual-fuel mode.

Dual fuel conversion allows the engine to operate on gas mixtures ranging from 50% to 70% + of total fuel consumed. Engines converted to Dual-fuel functionality exhibit diesel-like performance in critical areas such as efficiency, stability and load acceptance.

The smarter fuel choice to power your homes and workplaces

Pollution reduction and emission control

With rising pollution levels and the emphasis on cleaner emissions, our Kit has been specially designed and developed to ensure that a cleaner and greener fuel is used to generate power in the future.

Low capital cost

Use the Kit on any existing DG Set from 40 kVA to 2500 kVA.

Rapid return on investment and savings on operational cost

A future operational cost reduction of approximately 35%-45% per hour of use.

No change in existing power output of the DG set

Do not compromise on your power needs.

Statutory compliances

By converting the existing DG set the generator will come into compliance with government order and can be operated all year round, without worrying about adverse action during the DG ban period.

Post the NGT’s passing of an order* on the DG ban, the Haryana Pollution Control Board and Tamil Nadu Pollution Control Board have also issued the following orders reiterating the NGT order, and enforcing the conversion of diesel gensets to partial Gas based gensets.

*Our kit complies with the order of the NGT –(non attainment cities not meeting the standards of air quality) dated 6th August 2019. {Page no. 16, point 7(b.)}